Special rubber items and accessories

Special product and accessory categories collect all those rubber articles presenting unique and highly customized features.

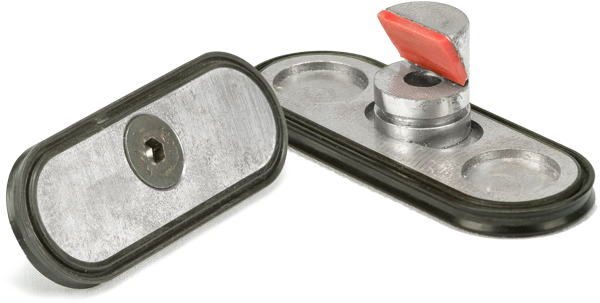

Bumpers

60ShA Natural rubber bumpers, molded by means of injection on a steel plate and on a M16 screw.

Its peculiar geometry and the amount of rubber, beyond 2kg, gives the product great damping properties even under extreme loads.

Furthermore the black color is made by adding carbon black to the compound which protects the rubber from weather agents, such as rain and especially sunrays.

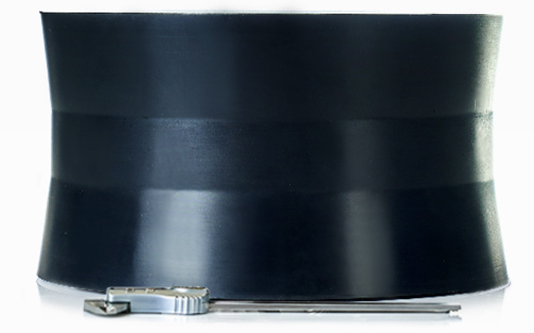

Sponge holder carpet

This carpet has been designed to hold inside a sponge filled with disinfectant or any other liquid.

In this 2020 we have to deal everyday with the pandemic, and it’s everyone’s duty to reinvent the hygiene concept!

Even a simple act, such as cleaning shoes on a cleansing surface, before entering any places could help our fight against viruses and bacteria.

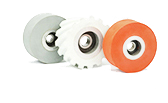

Pumping Pistons

These are the last special products made from Effegomma: they are made of a cast iron hub, coated with a low friction rubber.

They are used inside trucks which pump concrete at a very high height.

There are different types of them depending on the load of concrete to move and the diameter of the pipes where they run in.

Hourglass shape

This special shape helps fitting the piston inside the pipe and it guarantees the best sealing. In fact both the upper and lower seal can be compressed while mounting the piston inside the pipe, and when they are released both seals decompress and get in touch with the inner pipe wall. This contact is so “intimate”, that no concrete could spill out while pumping it.

Perfect seals

The sharp edges of the seal are critical. No dents, cuts, air bubbles or lack of material are allowed. This area is what keeps the concrete separated from the shafts and the engine, which moves the pistons.

Effegomma, probably the only italian company as stated by our customers, manufactures these items by means of injection. So we can guarantee every seal is perfect and exactly the same between each other even in a big batch production, because the rubber enters the mould while it is already closed, so we have no problem caused by exceeding rubber on the mold closure.